Battery manufacturing is a complex process that involves the careful management of various raw materials, such as lithium, cobalt, and nickel. These materials are not only expensive but also sensitive to storage conditions and handling processes. As the demand for batteries, especially in the electric vehicle (EV) and renewable energy industries, continues to rise, effective management of battery raw material inventories has become increasingly critical. In this context, Radio Frequency Identification (RFID) technology offers an innovative solution for optimizing warehouse operations, improving traceability, and ensuring quality control in the storage and handling of battery materials.

1. Overview of RFID Technology in Warehouse Management

RFID is a wireless system consisting of tags and readers that use radio waves to communicate. RFID tags are attached to items or containers, while RFID readers detect and read these tags to capture the data they contain. This data can include information about the item, such as batch numbers, expiration dates, and storage locations. The information gathered is then integrated into Warehouse Management Systems (WMS), providing real-time insights into stock levels, material locations, and operational efficiency.

RFID is particularly advantageous in warehouse environments because it allows for non-line-of-sight scanning, which enables rapid and accurate inventory counting without the need to physically handle or scan each individual item. This feature is critical when managing battery raw materials, where safety, speed, and precision are essential.

2. Applications of RFID in Battery Raw Material Warehouse Management

2.1 Real-time Inventory Monitoring

One of the most important applications of RFID in warehouse management is real-time inventory tracking. In traditional systems, battery raw materials are often tracked manually, which can be error-prone and time-consuming. With RFID, each pallet, container, or individual raw material unit can be equipped with an RFID tag that stores key information, such as material type, batch number, weight, and storage conditions.

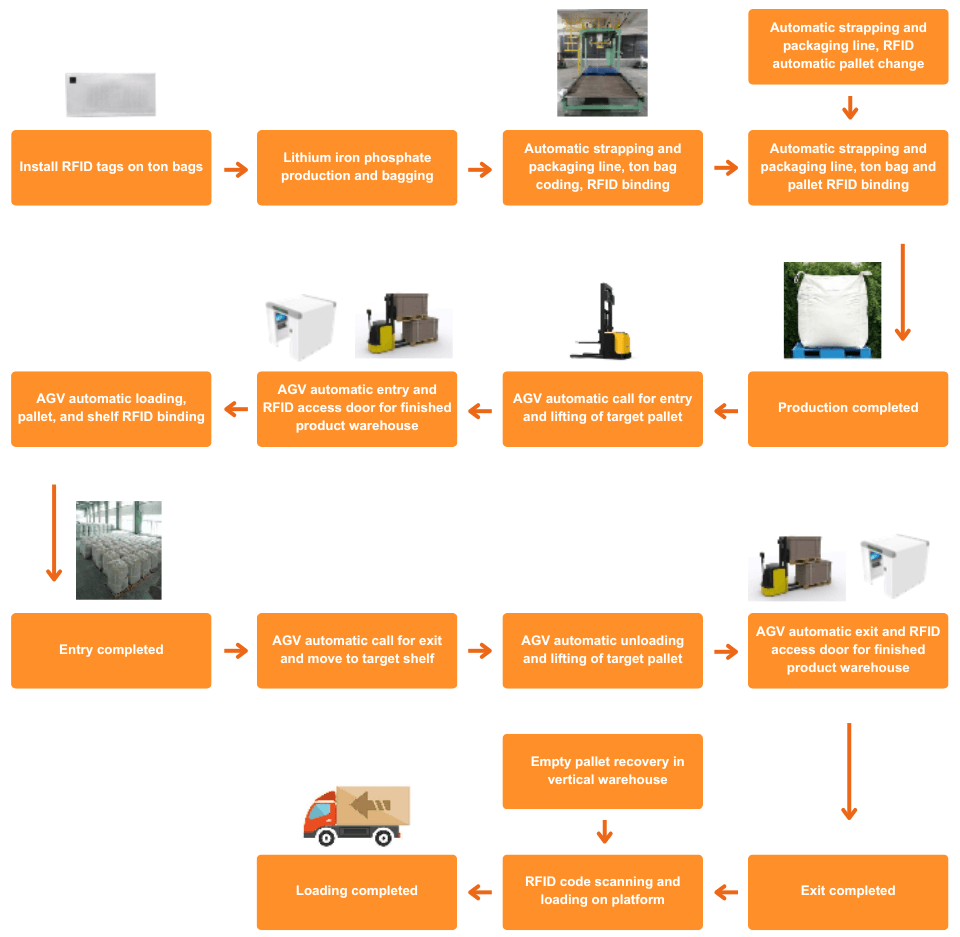

As materials enter or leave the warehouse, RFID readers located at strategic points—such as loading docks, storage areas, and entry/exit points—automatically detect the movement of tagged items. This allows for continuous, real-time monitoring of inventory levels without the need for manual intervention. As a result, warehouse managers have up-to-the-minute data on stock levels, helping to prevent material shortages or excesses and ensuring that production lines are adequately supplied.

2.2 Automated Processes and Improved Efficiency

RFID technology enables significant automation in warehouse operations, improving the overall efficiency of processes such as receiving, storage, and dispatch. Upon receiving a shipment of raw materials, RFID readers can instantly identify and log the details of each item without requiring workers to manually scan or enter data. This reduces the time spent on manual tasks, minimizes the risk of human error, and ensures that inventory records are accurate.

In terms of storage, RFID systems can assist warehouse staff in quickly locating specific materials. For example, if a production line requires a particular batch of lithium or nickel, the WMS can guide staff to the exact location using RFID tracking data. This eliminates the time wasted searching for items and ensures that materials are delivered to the production floor promptly.

Additionally, RFID facilitates automated stocktaking. Instead of manually counting inventory, which is labor-intensive and disruptive to operations, RFID readers can perform quick and accurate scans of entire storage areas. This automation significantly reduces the time and labor costs associated with physical inventory counts, while also improving accuracy.

2.3 Enhanced Traceability and Compliance

In the battery industry, traceability is crucial due to the stringent safety and environmental regulations surrounding the use of hazardous materials like lithium and cobalt. RFID tags can store detailed information about the origin, composition, and handling history of each material batch, enabling comprehensive traceability throughout the supply chain.

In the event of a quality issue, RFID systems allow for rapid tracing of problematic raw materials back to their source. This not only helps in identifying the root cause of defects but also assists in isolating affected batches, thereby minimizing the scope of any necessary recalls. Moreover, having access to accurate and detailed traceability data ensures compliance with industry regulations and quality standards, reducing the risk of fines or legal actions.

RFID technology also supports traceability during the transportation of raw materials between different warehouse locations or from suppliers to manufacturing sites. As trucks equipped with RFID readers pass through checkpoints, they automatically log the materials they carry, creating a digital trail that can be used to track the movement of goods.

3. Special Considerations for Battery Raw Materials

Battery raw materials present unique challenges for warehouse management. Many of these materials, such as lithium and nickel, are highly reactive and must be stored under controlled conditions to prevent degradation or safety risks. Additionally, raw materials like cobalt are both expensive and rare, making effective inventory management crucial for minimizing losses and ensuring an uninterrupted supply for production.

3.1 Environmental Monitoring with RFID

To address these challenges, RFID systems can be integrated with environmental sensors that monitor factors such as temperature, humidity, and exposure to corrosive substances. These sensors can be embedded in RFID tags or placed strategically throughout the warehouse. If conditions deviate from the required thresholds, the system can trigger alerts, allowing warehouse managers to take corrective actions immediately.

For example, lithium-based materials must be stored in cool, dry environments to prevent unwanted chemical reactions. RFID tags with integrated temperature sensors can continuously monitor storage conditions and ensure that they remain within safe limits. In the event of a temperature spike, the system can alert staff to take corrective measures, preventing material damage or safety hazards.

3.2 Durability and Adaptability of RFID Tags

Another important consideration is the durability of RFID tags. Battery raw materials are often stored in harsh environments where they may be exposed to heat, moisture, or chemicals. Therefore, it is essential to select RFID tags that are designed to withstand these conditions. For instance, high-temperature or corrosion-resistant RFID tags can be used for materials stored in extreme environments.

Additionally, some raw materials may need to be stored in metallic containers, which can interfere with RFID signal transmission. In such cases, specialized RFID tags designed to work on metal surfaces or UHF (Ultra High Frequency) tags with longer read ranges can be employed to ensure accurate data transmission.

4. Case Studies: RFID in Battery Supply Chains

Several leading battery manufacturers have successfully implemented RFID solutions to enhance their warehouse operations and material traceability.

For instance, a major lithium-ion battery manufacturer uses RFID to manage its inventory of lithium, cobalt, and nickel, ensuring that these critical materials are readily available for production. By deploying RFID readers throughout its warehouse, the company has reduced material handling times and improved the accuracy of its stock records. Additionally, the ability to trace raw materials from suppliers through to finished products has strengthened quality control and regulatory compliance.

In another case, an automotive battery supplier uses RFID to track the movement of raw materials across its global supply chain. By tagging materials at the point of origin and tracking their journey through warehouses and production facilities, the company can monitor inventory levels in real time, reducing the risk of supply chain disruptions. Furthermore, the system’s traceability features allow the company to quickly address any quality concerns by tracing affected batches back to their suppliers.

5. Benefits of RFID in Battery Raw Material Management

The use of RFID technology in managing battery raw materials offers several key benefits:

Improved accuracy: RFID systems automate data collection, reducing the risk of human error and ensuring that inventory records are accurate and up-to-date.

Enhanced efficiency: By automating processes such as receiving, storage, and stocktaking, RFID significantly reduces the time and labor required for warehouse operations.

Increased traceability: RFID provides detailed information about the origin, handling, and movement of raw materials, facilitating quality control and regulatory compliance.

Real-time visibility: Warehouse managers have access to real-time data on inventory levels and material locations, allowing them to make informed decisions and respond quickly to changing production needs.

Conclusion

As the demand for batteries continues to grow, the effective management of battery raw materials becomes increasingly critical. RFID technology offers a powerful solution for optimizing warehouse operations, improving traceability, and ensuring the safety and quality of stored materials. By automating processes, providing real-time data, and enhancing traceability, RFID can help battery manufacturers streamline their supply chains and remain competitive in a rapidly evolving industry.